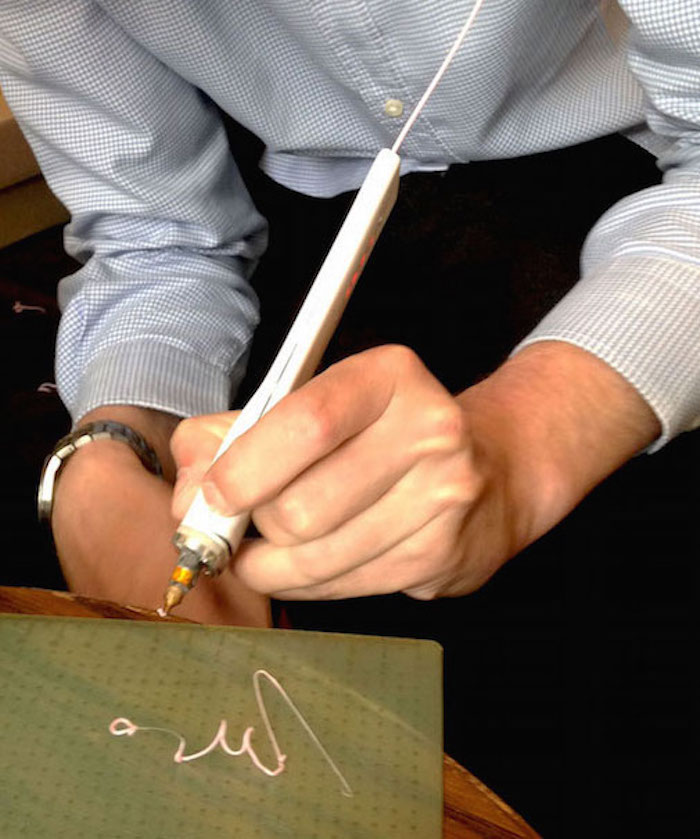

3D Simo CEO David Paskevic feeds plastic into a prototype of his new 3D mini pen. Image Courtesy: Hilary Brueck

The advent of 3D printing is all the rage these days. The drop in 3D printer prices, coupled with more powerful features, is driving this true and remarkable trend. The ability to design and/or print a seeming limitless variety of objects right in one's own garage is simply too alluring.

Presently, one can easily buy a 3D printer, download print ready fles of the web, buy necessary raw materials (for the printer itself) and viola!...a custom object. Yet it is the design of the fles themselves that is the one remaining bottleneck. Design, up to this point, has been a highly-technical task.

To create printable, 3D designs, software such as CAD or Solidworks is often employed, which are the same, highly technical programs that engineers and architects use for their professional work. And even with such elaborate programs running, computers can be quite limiting from a design perspective. This is especially true when it comes to creating more complex, organic shapes.

Enter the age of 3D design pens, which allow users to forego the need for the computer and 3D printer altogether and simply draw lines of fast-hardening plastic directly into 3D space. This method of dispensing material, direclty, in 3D, it's like drawing in the air. It allows for true variability, even emotion, to make its way into 3D shape creation.

3D printing guru, and high school technology teacher Phillip Cotton says, "if the toolshed of the 20th century was dominated by physical tools like a hammer or a wrench, the 21st century “shed” will be all about designing your own homegrown fxes and hacks—with 3D printing models."

“What can you do with a 3D printer?” Cotton asks, answering that the options are “endless.” From home basics like replacing cooking knobs and mending his fence, to shaping original bow-ties for the high school prom, he does it all with his 3D printer.

Teacher and 3D-modeler Cotton says in regards to 3D pens, "that’s a great way to start of, teaching future modelers the concept of extrusion, or shaping objects in space. Play is where it begins." He used to provide his high school students with pens to experiment, but says now the teenage designers just use CAD software. Even with advanced software, in 3D, some play is required.

Polyes Q1 is the first 3D printing pen that does not use heat to cure its ink. Very safe, very fast...highly innovative. Image Courtesy: Future Make

Recommended 3D Pens

As for specifc products in the 3D pen space, here are three of the top choices found by perusing the best reviews on the web. Note: some are immediately available, others are kickstarter campaigns that (from all information noted) will result in shipped product:

3Doodler

The 3Doodler is one of the most common and well-reviewed 3D pens out there. This is the tool of choice by Phillip Cotton, who actually created the below bust with this particular pen.

The 3Doodler 3D pen...an affordable, solidly-performing tool. Image Courtesy: 3Doodler.com

3DSimo Mini

Check out the different functions of the 3DSimo Mini, a portable 3D printer pen that many creative artists will love. Image Courtesy: 3DSimo | Kickstarter

San Francisco-based startup 3DSimo has launched a Kickstarter campaign for its revolutionary tool 3DSimo Mini, a 3D printing pen with interchangeable tips that can burn designs onto wood and leather, cut foams and rubber-like materials cleanly, and even solder metal with adjustable temperature settings up to 490 degrees Celsius or 914 degrees Fahrenheit.

With its ergonomic and minimalist case design, the 3DSimo Mini is a light and compact 3D printing pen that can melt a variety of materials to form striking sculptures and 3D drawings.

Click here to watch the 3DSimo Mini video...it is very, very impressive.

Image Courtesy: 3DSimo | Kickstarter

Polyes Q1

Polyes Q1 is a highly innovative offering in the 3D pen space, allowing for easy and fast designs to be produced with nearly zero safety issues. Image Courtesy: Future Make

What makes the Polyes Q1 drastically diferent from other 3D printing pens, like that of the 3Doodler, is that instead of melting strands of plastic, which can be a bit dangerous, it uses stereolithography (SLA) technology to cure a phototosentive resin. The pen will eject a liquid resin from the extruder, then almost instantly a UV light will cure that resin, solidifying it, as the user draws a 3D object.

Such technlogy has other advantages, besides the safety benefts. For one, the resin is hardened almost immediately, not requiring a period of time to cool down like the molten plastic extruded from devices like the 3Doodler. This means that objects can be ‘printed’ faster, and more reliably with the Polyes Q1 pen. Additionally, unlike the melting of PLA and ABS thermoplastics, the release and curing of the resin used in the Polyes Q1 emits no odor or possibly harmful fumes. It is a great tool for novices and kids in particular, looking to get started designing in 3D space.

Order your PolyesQ1 pen via this kickstarter link. The frst batch of pens has already shipped to the campaigns initial backers.

Let the creating begin.

This post is featured in The Ammonista Report - Fall 2015: quarterly inspiration to help people and companies create brands of significance. Subscribe Here.